Acoustical Analysis

Our acoustical analysis services optimize the performance of reciprocating compressor and pump systems to minimize pulsation effects and maximize performance while adhering to industry limits of vibration, pressure drop and horsepower loss.

Tech Transfer has extensive experience conducting acoustical pulsation analysis on reciprocating gas compressors and liquid pumps. Analysis techniques have been developed over the last 25 years that help to ensure our computer analysis results closely match recorded field data.

API 618 PULSATION ANALYSIS

- Digital modeling of system

- Dynamic pulsation simulation

- Evaluation of pulsations and shaking forces per API 618

- Pressure drop calculations

- Corrective recommendations

Tech Transfer’s success rate with pulsation analysis is unparalleled in the reciprocating compressor industry. Tech Transfer initially developed pulsation analysis technology to support its field vibration analysis of compressors. After numerous successful field analyses, Tech Transfer began offering pulsation analysis on new equipment during the design phase in order to prevent field issues from occurring. Today, Tech Transfer is a world leader in the pulsation and vibration analysis of reciprocating compressors. We perform pulsation analyses in complete compliance with API 618 and all its options for stress and dynamic analysis.

Download our Acoustical Analysis Request Form

Once you have downloaded the form, please fill out and email to: sales@techtran-hou.com

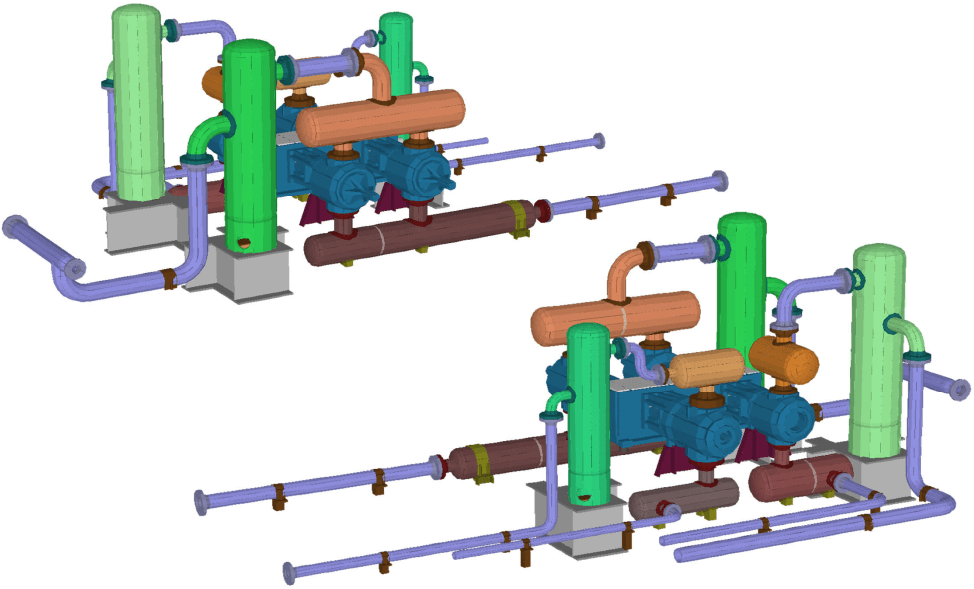

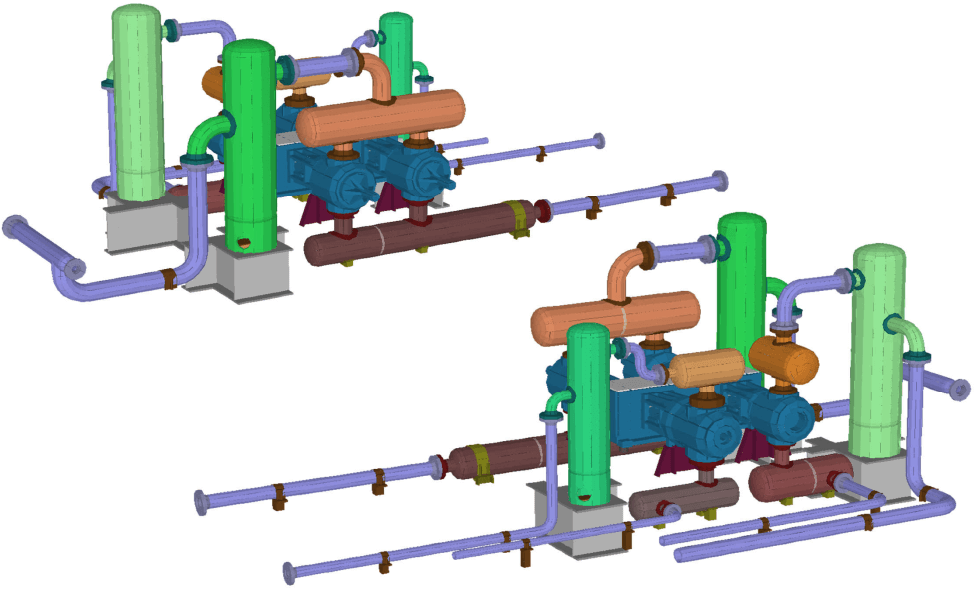

Piping Stress & Dynamic Analysis

Our piping analysis services help users control the vibration energy associated with rotating equipment piping systems to eliminate fatigue failures, downtime and repairs. We offer both on-skid and facility piping systems analysis.

Tech Transfer has extensive experience in performing piping studies for reciprocating compressor, rotating equipment, and process industry applications. Our studies are performed in accordance with the applicable industry standards for both dynamic (API 618) and stress analysis (ASME B31.3, B31.8, and others). Our modeling techniques reflect the continuous improvement that results from remedial field work. Tech Transfer’s support designs ensure that predicted vibrations are adequately controlled and pipe stresses fall under the applicable piping code allowable stress.

Applicable Codes

- API 618 (Reciprocating Compressors)

- API 674 (Reciprocating Pumps)

- Piping MNF Analysis

- Piping Forced Response Analysis

- API 619 (Screw Compressors)

- API 617 (Centrifugal Compressors)

- API 661 (Air Cooled Heat Exchangers)

- API 610 (Centrifugal Pumps)

- ASME Section VIII DIV. 1 & 2 Vessel Nozzle Load Analysis (Boiler & Pressure Vessel Code)

- ASME B31.3 (Process Piping)

- ASME B31.8 (Gas transmission & Distribution Piping Systems)

View Our Piping Analysis Services Presentation

Tech Transfer’s success rate with piping analysis is unparalleled in the reciprocating compressor industry. Our piping analysis methodology was originally developed in order to support our field vibration analysis of compressors. Today, Tech Transfer is a world leader in the piping stress analysis and piping vibration analysis of reciprocating compressors. In addition to API 618 studies for reciprocating compressors, Tech Transfer can also provide pipe stress studies servicing the process, oil and gas industries in compliance with ASME B31.3, B31.8, and other applicable codes and standards.

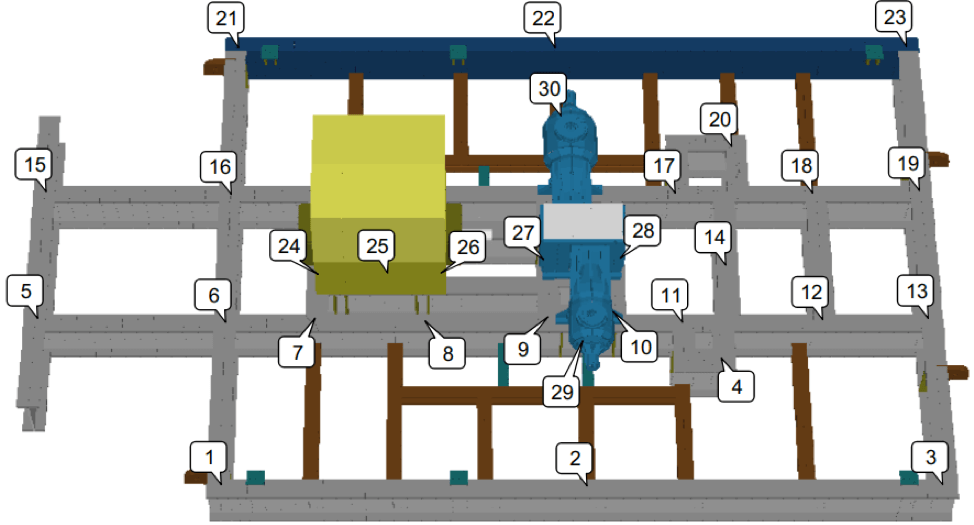

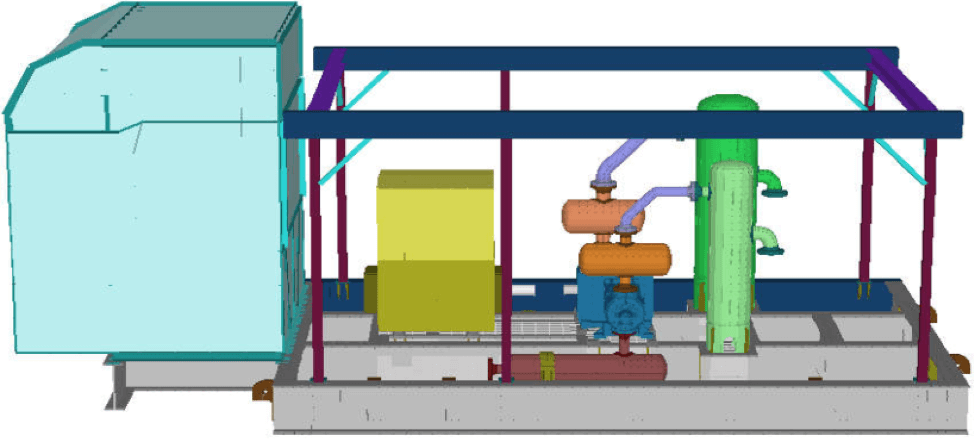

Skid Analysis

Along with vessel dynamic analysis, our skid analysis services are aimed at optimizing the design and installation of rotating equipment to improve reliability and control the effects of vibration energy that leads to fatigue failures, downtime and repairs.

Tech Transfer has the capability to perform stress and dynamic analysis for reciprocating package skids of all sizes. We have extensive experience in analyzing wind, seismic, transportation and lift conditions. We also perform natural frequency analysis and simulation of operating vibration levels.

Tech Transfer performs stress analysis on lifting lug designs per AISC and RP2A and will provide recommendations if required. In addition, we provide predicted sling loads and support reaction values.

Tech Transfer has experience in analyzing FPSO compressor modules and offshore platform decks. We include the ship / platform deck in order to achieve an accurate dynamic model.

Tech Transfer has developed FEA models and modeling techniques to match field vibration results. The major equipment, skid and pedestal, are modeled using 3-dimensional shell elements in order to achieve the highest level of accuracy. Our capabilities include the calculation of inertial unbalanced forces, crosshead forces and cylinder gas forces based on compressor performance.

Vessel Dynamic Analysis

Our vessel dynamic analysis services evaluate vessel mode shapes to help ensure the avoidance of mechanical resonance.

Tech Transfer has the capability to provide accurate vessel dynamic analysis per API 618 5th edition. We will evaluate vessel mode shapes and ensure mechanical resonance is avoided. Forced response analysis will be performed in order to calculate predicted vibration levels across the entire operating range of the compressor. When necessary, recommended modifications will be provided in a timely manner.

Based on our extensive field experience, we have developed FEA models. The compressor frame, cylinders, pulsation bottles, scrubbers and piping are modeled using 3-dimensional shell elements to achieve the highest level of accuracy. Tech Transfer has the capability to calculate inertial unbalanced forces, crosshead forces and cylinder gas forces based on compressor performance.

Field Vibration Analysis

On July 1, 2023, we expanded our Field Engineering capabilities by opening TTI Field Engineering, Inc.

TTI Field Engineering provides a range of engineering services that specifically cater to troubleshooting equipment operation and detecting performance issues. In addition to the high-quality field vibration monitoring and analysis, new diagnostic capabilities which allow us to provide a complete analytical solution for the entire package of operating equipment. Our field vibration analysis services deliver effective vibration and pulsation data collection to identify sources of vibration energy, identify equipment issues and provide comprehensive engineered solutions that will improve reliability and safe operation.

For more information, please visit TTI Field Engineering’s website. http://www.ttifieldengineering.com

Foundation Analysis

Our concrete foundation analysis services help in the design of foundations for a wide range of reciprocating compressor horsepower levels that ensure low stresses, effective dissipation of unbalanced forces and even settlement.

Leveraging our expertise gained over the last 30 years, Tech Transfer has completed the design and analysis for some of the largest reciprocating compressors installed on concrete foundations.

Tech Transfer is capable of designing foundations with pilings or drilled piers. We understand the pros and cons associated with skid mounting versus block mounting compressors. To verify the design, foundation stresses and dynamics are calculated using detailed FEA models that include concrete, rebar, anchor bolts, equipment, skids and soil properties.

Tech Transfer supplies foundation construction drawings along with bill of materials, grouting procedures, concrete specifications, soil preparation notes and installation comments.

Our multi-layer rebar design provides energy transmission and resistance to crack propagation.